U形管式换热器设计

摘 要

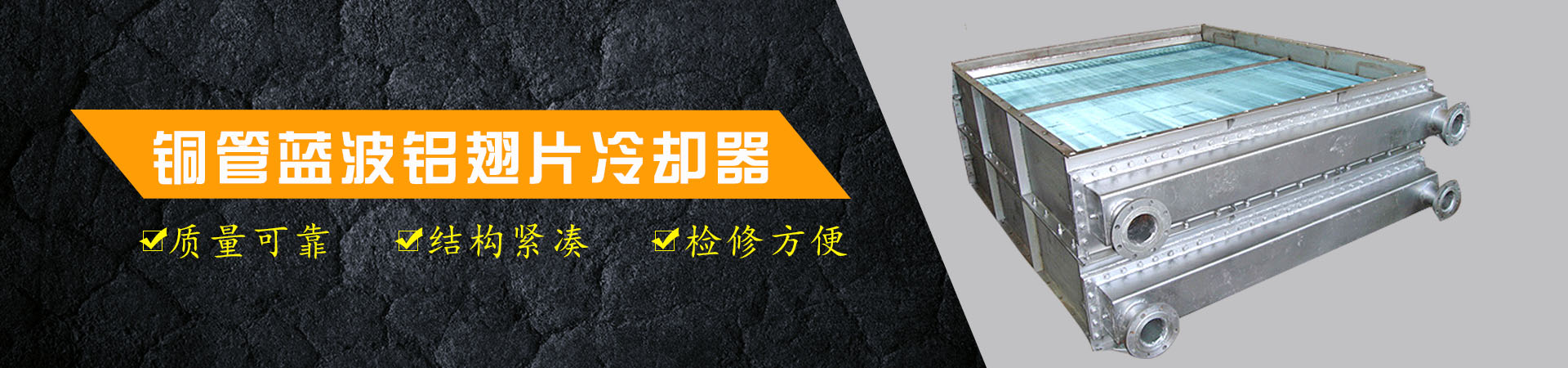

换热器是广泛应用于汽车、航空、石油化工、动力、医药、冶金、制冷、轻工、食品、工程机械等行业,约占工艺设备总量的20%~70%。按其传热面的形状和结构进行分类可分为管型、板型和其他形式换热器。目前常用的换热器种类有浮头式、固定管板式和U形管式,其中以浮头式换热器居多。固定管板式换热器由于自身结构,应用的场合有限;浮头式换热器零部件多,易拆卸和清理,但检修的工作量大,容易内漏;而U型管式换热器的管板比固定管板式换热器少,其泄漏点就相应减少。此外,U型管式换热器的壳程水压试验后烘干也比较容易,而且它的适用场合广、检修简单、操作弹性好。如果换热器的换热面积小、壳程与管程的温差较大或壳程介质很容易脏、管束表面需要经常清理地,一般都采用U型管式换热器。

Heat exchanger is an important equipment in chemical production process, it can realize heat exchange between medium, widely used in automotive, aerospace, petrochemical, power, refrigeration, light industry, food, medicine, metallurgy, engineering machinery and other industries, accounts for about 20% ~ 70% of the total process equipment. According to the heat transfer surface shape and structure of classification can be divided into tube type, plate type heat exchanger, and other forms. At present commonly used type heat exchanger has floating-head type, fixed tube plate and U tube type, of which the majority of floating head heat exchanger. Fixed tube plate heat exchanger due to its structure, the application of limited occasions; Floating head heat exchanger components, easy disassembly and cleaning, but maintenance workload is big, easy to leak; And the U tube heat exchanger tube plate less than fixed tube plate heat exchanger, the leak will decrease accordingly. In addition, the shell side of the U tube heat exchanger after drying is also easier, water pressure test and its wide application occasions, simple maintenance and good elasticity of operation. If heat exchanger heat transfer area is small, the shell side of the shell side and tube side temperature difference is bigger or medium it is easy to dirty, bundle need often clean up the ground surface, generally USES the U tube heat exchanger.

With reference to the design of GB150-2011, GB151-2011 references, such as comprehensive consideration of various factors need to select suitable and reasonable structure design, the structure of the economy. U-tube heat exchanger is

部分内容来源于网络,仅用于学习分享,如发现有侵权,请及时联系删除,谢谢。