摘要

换热器是化工生产中重要的设备之一, 它是一种冷热流体间传递热

量的设备,其中管壳式换热器应用*为广泛。本设计为单壳程、四管程

的卧式固定管板式换热器,管程介质为水,壳程介质为水蒸气。水的流

量为 175t /h,管程的工作温度为 80℃,壳程的工作温度为 167.55 ℃。

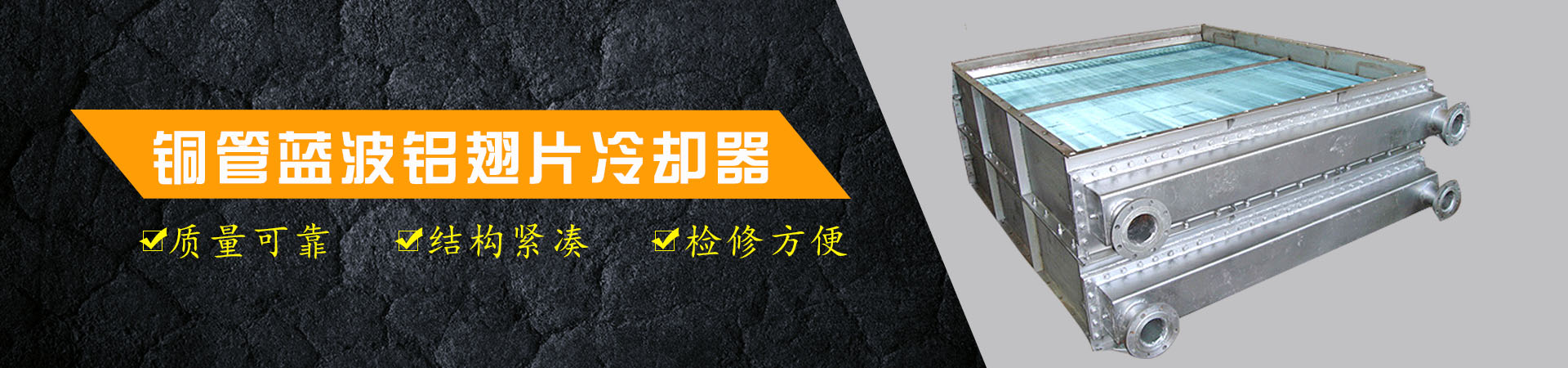

固定管板式换热器是由两端管板和壳体连接而成, 因此它具有结构

简单和造价低廉的优点。 其结构特点是管束连接在管板上,管板与筒体

焊接。

在其结构上安装有九块弓形折流板,以增加流体的湍流程度。接管

法兰均选择板式平焊法兰, 选用鞍式支座,本次设计主要分为两个部分,

一部分是传热工艺计算, 另一部分为强度计算。其中固定管板的计算较

为复杂,也是至关重要的环节。而且本设计中,管板的延长部分还兼做

法兰。 为了减少热应力, 通常在固定管板式换热器中设臵柔性元件来吸

收热膨胀差。 但本次设计对温差应力进行研究后, 不必安装柔性元件来

减少热应力。

换热器作为传热设备随处可见, 在工业中应用非常普遍, 特别是耗

能用量十分大的领域, 随着节能技术的飞速发展, 换热器的种类开发越

来越多。

关键词: 换热器;折流板;法兰;管板

Abstract

Heat exchanger is one of the important equipment in chemical

industry , it transfer heart between cold and heart fluid. In this heart

exchanger the tubular heart exchanger is most widely used. This design is a

fixed tube-sheet exchanger of one shell and one tube, water flow in tube and

steam flow in shell. The flow of water is 120t / h, the tube's working

temperature is 90℃, the shell of the operating temperature 175℃.

Fixed tube-sheet exchanger is connected with tube-sheet which fix in

both side and shell. For this simple structure, it have low price. It Structure

characteristics is the tube connect in the sheet which seal with the shell.

There are nine baffle plate fixed on this structure to increase the flow rate.

This design include two parts ,one is heart transfer process the other is

strength calculate. During this calculate the tube-sheet is more complex but so

important.

In order to absorb the difference of the heat bulge,the pipe fixed heat

exchanger is equiped with floxible element, In this design it is impossible to

arrange for the flexible element throu

部分内容来源于网络,仅用于学习分享,如发现有侵权,请及时联系删除,谢谢。