连续型和锯齿型螺旋翅片管翅片效率计算和分析

摘要:

介绍了烟气换热领域常用的两类高频焊钢质螺旋翅片管.指出目前存在多种连续型与锯齿型高频焊螺旋翅片管翅片效率计算方法,不便于同类换热实验结果的相互比较.通过深入分析与计算比较,对连续型与锯齿型高频焊螺旋翅片管分别给出了建议的翅片效率计算方法,供相关的工程设计及实验研究选用.两种管型的翅片效率比较表明,锯齿翅片的翅片效率较高,提高的幅度随翅片高度增大而增大.

关键词:

余热锅炉; 螺旋翅片管; 连续型翅片; 锯齿型翅片; 翅片效率

中图分类号:TK 223 文献标志码:A

Calculation and analysis of fin efficiency of solid and serrated helical-finned tubes

MA You-fu, YUAN Yi-chao

(School of Energy and Power Engineering, University of Shanghai for Science

and Technology, Shanghai , China)

Abstract:

This paper introduced two types of helical-finned tube which are manufactured by high-frequency resistance welding and widely applied to various flue gas heat exchangers. However, various methods for calculating the fin efficiency of solid and serrated helical-finned tubes have been used in the literature, which makes it inconvenient to compare the experimental results of helical-finned tube heat transfer by different researchers. Based on a comprehensive analysis and comparison, the calculation methods of fin efficiency of solid and serrated helical-finned tubes were recommended for the design of heat exchanger and the processing of experimental heat transfer data. The comparison of fin efficiency between the solid and serrated fin tubes indicated that the serrated fin has a higher fin efficiency than the solid fin, and the fin efficiency difference between the two types of finned tube increased with the increase in fin height. The fin efficiency of the serrated fin tube is approximately 15% higher than that of the solid fin tube when the fin height is equal to 28 mm; the fin efficiency of the serrated fin tube is only 1% higher than that of the solid fin tube when the fin height is equal to 12 mm.

Key words:

HRSG; helical-finned tube; solid fin; serrated fin; fin efficiency

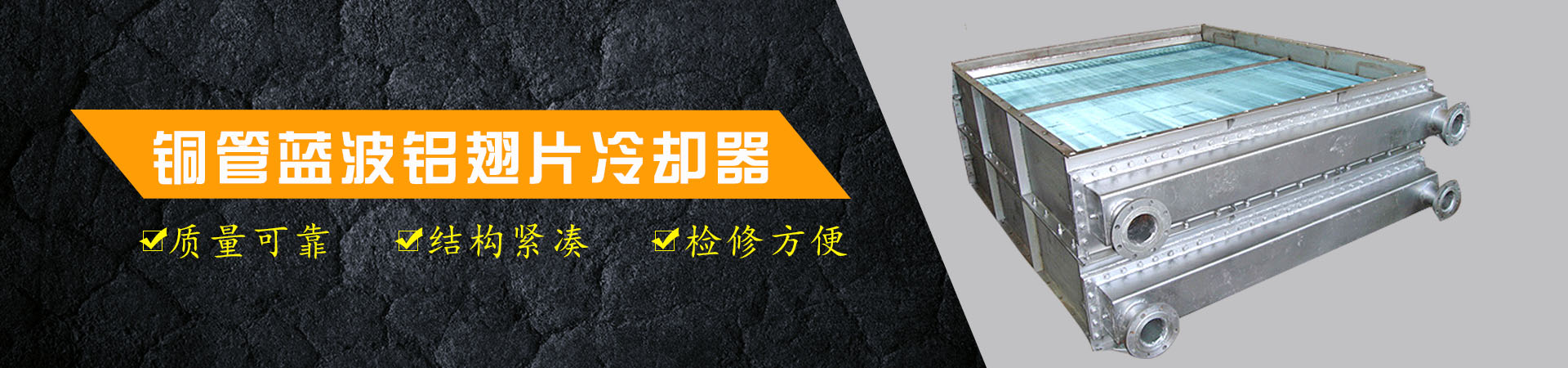

在联合循环余热锅炉、化工废热锅炉等大型高温烟气换热设备中,通过高频电阻焊接技术制造的螺旋翅片管(翅片材质为碳钢或合金钢)得到了广泛应用.实际应用的高频焊螺旋翅片管分为连续型与锯齿型两大类,如图1所示.其中,d0为基管外径;df为翅片外径;hf为翅片高度;pf为翅片螺距;hs为锯齿高度;ws为锯齿宽度;δf为翅片厚度.锯齿型